How nonprofit CHERP Solar Works

is empowering underserved

communities across the U.S.

There’s no doubt that the renewable energy revolution is under way. But we must build and execute it equitably, rather than by re-creating the systems that have led to the current climate crisis and economic inequality.

At Seneca Environmental, we believe that an equitable renewable energy economy must go beyond fairness. It must prioritize ownership of renewable energy assets by Native communities and others who have been historically underserved and disproportionately negatively impacted by the fossil-fuel economy.

To show how this can be done, we recently hosted a webinar about a business model innovation that locks the benefits of the renewable energy transition for frontline communities. In Let’s Build Solar Panel Factories for Underserved Communities, nonprofit CHERP Solar Works™ founder Devon Hartman shared what makes this model so powerful.

Micro solar panel factories

Source: CHERP Solar Works

The U.S. is set for a domestic solar panel manufacturing renaissance supported by the federal government, but most of the factories in the works are mega factories that rely heavily on automation and foreign investment. CHERP, in contrast, wants to help communities build locally owned “micro” solar panel factories in underserved communities across the U.S., focusing heavily on workforce development. These factories will attract investment and resources to local economies, regenerating them from the ground up.

Beyond fighting climate change, CHERP aims to bring back middle-class manufacturing jobs and stimulate local economies. That takes more than just creating jobs — it also requires supporting local ownership and locating the entire value chain inside the local community, so that profits are recirculated locally as many times as possible.

CHERP doesn’t plan to achieve this single-handedly; their model relies on inspiring local nonprofit ownership of production capability by groups around the country. Seneca Environmental believes in models like this because we know that it will take unprecedented collaboration to accelerate the transition to renewable energy equitably at the speed and scale that’s needed.

How do we compete with China?

Although 80% of solar panels used in the U.S. are imported, it doesn’t have to be this way.

Hartman is regularly asked how his company can possibly compete with China and other Asian countries. He has answers. CHERP’s combination of two powerful factors gives them a strategic advantage:

- CHERP plans to distribute the most advanced solar technology in the world.

- CHERP’s blended nonprofit-for-profit business model will allow them to cost-effectively deploy the technology.

Advanced solar technology

CHERP has radically simplified the solar manufacturing process, resulting in fewer and less expensive materials and parts. Because their modules are more powerful and have a longer lifespan, their levelized cost of energy (LCOE) is competitive with that of any others on the world market.

To validate their advanced solar technology, CHERP partnered with Harvey Mudd College and Physics Professor Emeritus Dick Haskell, who tested and modeled the technology for four years. Haskell showed that CHERP’s technology has completely eliminated reverse bias, which causes hotspots in solar panels — a problem that has plagued the solar industry since it began and that is only getting worse as the efficiency of the cells increases.

Fires and electrical shock incidents have also plagued the industry. CHERP’s modules shut down automatically in a millisecond if they do not sense an inverter, making them safe for firefighters, and can never create a plasma arc, which can burn down an entire building. The modules are extremely safe and efficient.

Blended business model

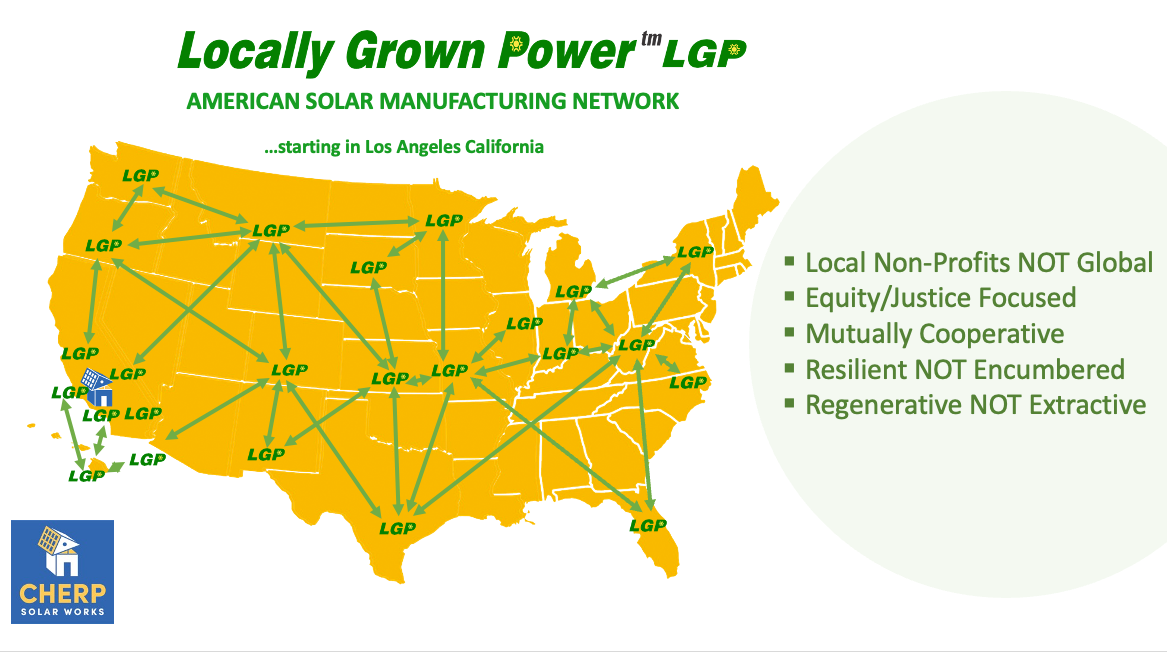

Each CHERP factory will be independently owned by a nonprofit within an underserved community. Each locally owned solar factory will then be united into the national Locally Grown Power™ (LGP) factory network, itself a nonprofit. Their nonprofit status will allow them to take advantage of the many opportunities available to 501c3s, such as grants and endowments; the nonprofits can also potentially partner with third-party owner investment companies with tax appetites who can take advantage of the Investment Tax Credit (ITC) and depreciation (MACRS).

The CHERP business model, combining Locally Grown Power with third-party ownership. Source: CHERP Solar Works

In fact, the first prototype factory, which CHERP has built in Pomona, California, was primarily funded by a grant from the State in addition to donations from donor-advised funds, private grants, and foundation endowments. The factory is expected to produce modules by the end of the year with zero capital expenses to amortize into their product cost. For future projects, CHERP can also partner with tax equity partners.

The nonprofit model allows CHERP to combine the “best of all worlds” with the tools available in the U.S. economy. That helps CHERP compete with Chinese panels, whose prices are controlled by the Chinese government. CHERP can use all of the sophisticated levers and dials available to both nonprofits and for-profits to bring their prices in line with the world market.

Massive economic benefits for communities

CHERP’s most significant innovation is relocating the economic driving force of solar energy production. Currently, any community that wants to deploy solar must spend 20%–25% of its investment on panels that come from outside the community. That money generally leaves not only the local community but also the state and the country — creating a massive billion-dollar trade deficit at the federal level.

Individuals, too, are sending their energy dollars out of the community. If each of the 6,000 lowest-income households in a community spends $90 per month on electricity, that adds up to about $6.5 million per year that these families are sending out of the community to the utilities. We can capture that “economic leakage” by making and distributing energy within communities.

A virtuous economic cycle

How do we make it happen? CHERP has engaged local municipal governments, anchor institutions, the Chamber of Commerce, and the state of California to launch the first CHERP factory in the Pomona community.

That factory will hire local workers who may be able to walk or bike to work, helping to lower emissions. The products and services created will be used in the local community, creating a virtuous economic cycle.

Because Pomona gets its power through a community choice aggregation (CCA) agency, when the panels from the factory are deployed in the community, that power will go directly to the 6,000 lowest-income families, as well as to many others. This redirects that $6.5 million per year and more back into the local economy. To directly address justice and equity issues, CHERP plans to provide free energy to the lowest-income households, funded by energy sale profits. Lower-income families are much more likely than others to spend extra dollars in the local community, which means the retail economy in the community grows, hiring more local employees.

In this virtuous economic cycle, profits are reinvested in the local community, generating economic activity — including increased tax revenues — that can quickly pay back any investment from the state.

A nationwide solar panel factory network

Source: CHERP Solar Works

CHERP envisions the locally owned factories being knit together in a national Locally Grown Power network of American nonprofit solar manufacturing — in effect a mega solar factory that can take advantage of economies of scale.

One factory alone could mitigate thousands of metric tons of CO2 and is expected to create over 700 direct and indirect jobs, stimulating the local economy by an estimated $147 million over 15 years. Using the scalable model developed in Pomona, CHERP aims to build out the Locally Grown Power network.

While CHERP’s goals are ambitious, the moment is opportune. Hundreds of people and organizations are ready to collaborate, and new federal programs and legislation are set to provide much-needed resources. CHERP is already discussing this buildout with 15 other cities around the country, and more are joining the conversation.

If you’re interested in starting a locally owned nonprofit solar panel factory in your community, click the button below.